OUR INFRASTRUCTURE

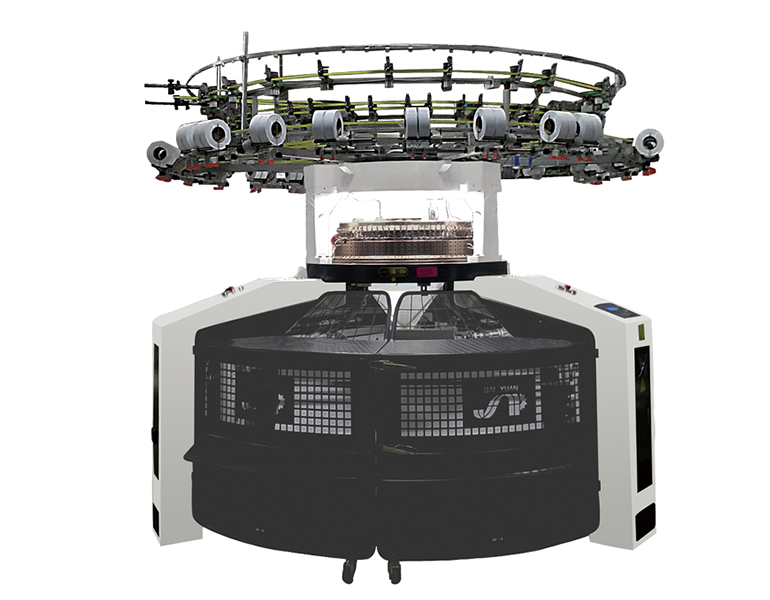

Knitting Machine

Our knitting unit is equipped with cutting-edge technology that enables us to produce high-quality knitted fabrics, catering to a wide range of industries including fashion and sportswear. With a focus on innovation, efficiency, and sustainability, we deliver a variety of knit structures and designs, customized to meet our clients’ unique requirements. From fine-gauge delicate knits to heavy-duty industrial fabrics, our knitting unit ensures superior quality and precision. Our knitting machine can create a wide range of stitches, including Rib, Jersey, Airtex, Honeycomb, Lycra Jersey, Fleece, and Mini Jacquards in any form or structure. This allows for the production of various fabrics, from basic to intricate designs. High-speed operation allows for rapid production, making the machine suitable for both small-batch and large-scale manufacturing

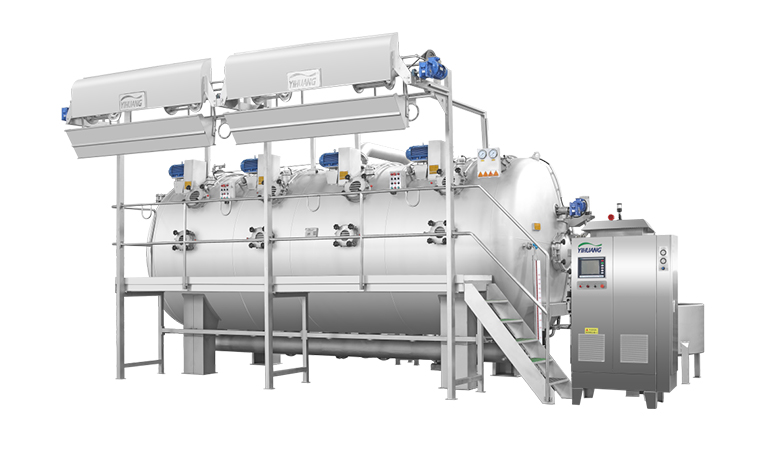

Dyeing Machine

Our state-of-the-art dyeing unit is equipped with advanced technology to ensure the highest quality, efficiency, and sustainability in fabric dyeing. We specialize in both small-batch and large-scale production, offering a variety of dyeing processes tailored to the specific needs of our clients. From natural fibers like cotton and wool to synthetic fibers such as polyester and nylon, our dyeing unit can handle a wide range of materials while maintaining precision in color matching and quality control.

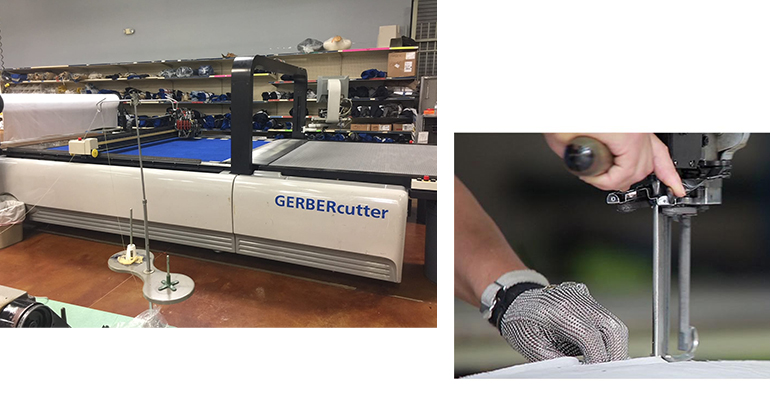

Cutting Machine

Our cutting unit is designed for efficiency, precision, and scalability, offering high-quality cutting solutions for a variety of fabrics and garment types. Equipped with the latest technology, our unit ensures optimal material utilization, minimal waste, and superior accuracy. Whether producing large batches or small custom orders, our cutting unit plays a crucial role in delivering perfectly shaped and sized fabric pieces for further garment manufacturing

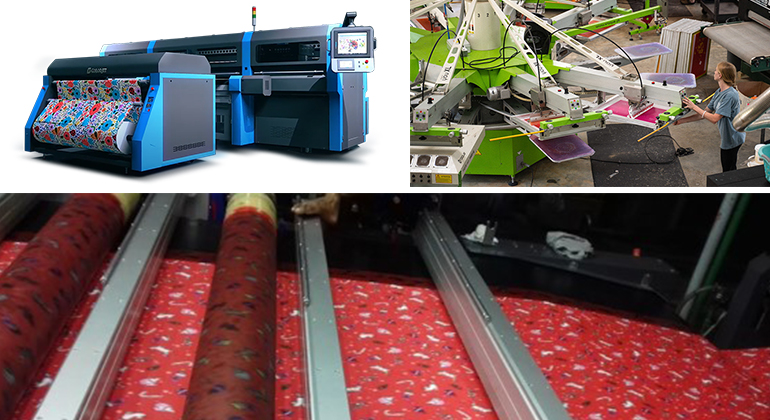

Printing

Transform your designs into high-quality textiles with our expert fabric printing services. At WW GROUP UK, we specialize in creating vibrant, long-lasting prints on a variety of fabrics, including cotton, polyester, and more. Whether you’re looking for custom apparel or promotional materials, our advanced printing technology ensures precise color reproduction and intricate detail. From small batch orders to large-scale production, we deliver eco-friendly, durable, and beautifully crafted fabric prints that bring your creative vision to life

Sewing

Giving life to our imagination and wings to our aspirations, our sewing facilities is the next step in the process that turns fabric into a multitude of garments with a capacity of 6000 pieces per day. Our product centric and dedicated sewing production lines across our plants turn customer sketches into reality irrespective of size shape or colour. Experienced operators across our factories are specially trained for specific product groups thereby allowing high efficiencies and consistency in every stitch.

Finishing and Packing

The final phase of the production process is of checking, ironing and packaging to ensure that every garment is in line with our customers vision. An in-depth final product inspection is carried out by our experienced quality control teams, keeping in mind high levels of globally accepted AQL standards. This is done in-spite of an end-to- end inspection process at every stage of the manufacturing process, this in turn ensures an error-free and contamination free product. The final products are then run through metal detection machines, before they are finally sealed into carton boxes in our special airport packaging metal free zones and are then ready for shipment

Certifications:

Oeko-Tex Standard 100

WW GROUP UK

We have our own production unit with ample workspace, natural ventilation, and individual parking spaces. Our state-of-the-art Brother and Pegasus oil-free machines ensure oil-free production. We use OMS software for process management and CAD software for accurate fabric programming and costing. Our dedicated merchandising, quality, lab, and accessories teams consistently meet customer requirements. Our Key Strengths are

SUSTAINABLE PRACTICES

Eco-Friendly Materials:

Using organic cotton, recycled polyester, and other sustainable materials.

Waste Reduction:

Implementing efficient production processes to minimize waste.

Ethical Labor Practices:

Ensuring fair wages, safe working conditions, and opportunities for professional growth for all employees.

MANUFACTURING EXCELLENCE

State-of-the-Art Facilities:

Our manufacturing units are equipped with the latest machinery and technology, enabling us to produce high-quality garments efficiently and sustainably.

Skilled Workforce:

We pride ourselves on our team of skilled professionals, including designers, engineers, and artisans, who bring their expertise and passion to every project.

Certifications:

FABRICS AND SPECIAL TREATMENTS TECHNOLOGY

Fabrics:

Cotton / Spandex, Polyester / Spandex, Modal / Spandex, Bamboo / Spandex, Bamboo / Cotton / Spandex, Polyester / Cotton / Spandex, Nylon / Spandex, Rayon / Spandex, Polyester / Rayon / Spandex, Tencel / Spandex, Custom Blend.

Fabric Treatment:

Antimicrobial, Antibacterial, UPF 50+ Protected, Odour Resistant, Flame Retardant, Moisture Wicking and Quick Dry PU Coating – Water Repellant.

Our Comprehensive Garment

Production Services

Pricing

Our experts deliver accurate garment pricing on the same day of inquiry, ensuring swift and reliable quotes based on detailed specifications.

Sampling

We collaborate closely with your team to create top-quality samples, ensuring they meet approval standards and serve as effective tools for sales.

Merchandising

Our dedicated merchandising team expertly manages all aspects, ensuring clear communication and effective coordination throughout the entire process.

Quality Assurance

We maintain rigorous quality checks at every stage, adhering to AQL 2.5 standards, with certified technicians ensuring defect-free production.

Shipment

We efficiently coordinate with forwarders and monitor trans-shipment points to ensure smooth and timely delivery.

Order Tracking

Stay informed with real-time updates on your order status through our responsive email and phone support.